Refining

By using recycled silver, you help reduce the need for mining. You support a circular economy — where materials are used again and again, respectfully and sustainably.

Our company has deep expertise in the field of refining different challenging raw materials about 30% of the world’s supplied pure metals are related to the recycling origin.

Once refined, recycled silver is identical to newly mined silver. It’s just as bright, just as strong, and just as perfect for crafting rings, necklaces, bracelets, and more.

Trust is measured in certifications. Our entire operation is governed by the most rigorous international benchmarks, including GIT & RJC practices, ISO production, testing and assaying norms.

Raw materials

Used jewelry

scrap

Industrial

scrap

Silver

concentrate

Fine product

Silver poweder

99,99%

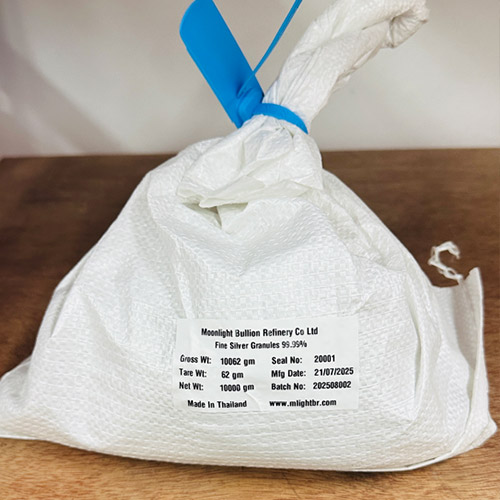

Silver grains

99,99%

Gold

grains

ARRIVAL OF MATERIALS

Delivery

to the site

- Commercial invoice

- Delivery note

Registration

of arrival

to the site

- Weighing

- Sampling

Assaying

- Certificate of analysis

- Quality confirmation

- Balance payment

Launch of

production

and refining

- Refining and recovery of metals

We Receive Materials with Care:

- Everything begins when silver-containing items arrive at our facility. This can be old jewelry, polishing dust, production off-cuts, or even used silver from factories

- Using advanced electrolysis and chemical processes, we separate the pure silver from any other metals or impurities. Our methods are efficient and clean, meeting international ISO standards. This means every step is monitored, measured, and certified.

- The purified silver crystal is formed into small, even grains (1,5–3mm). All silver during the process is oxygen free and melted in a protective atmosphere. These are easy to melt, easy to measure, and perfect for casting new pieces. They are uniform, bright, and free of black spots or oxides.

We pack the silver in secure, sealed bags and ship them directly to you, we ensure you get what you need, on time.

Other Services

Join Our Precious Metals Network

Receive timely market updates, expert insights, and exclusive offers on gold, silver, platinum, and palladium. Sign up and stay ahead of the market